EXPLORE

EXPLORE

EXPLORE

EXPLORE

EXPLORE

EXPLORE

EXPLORE

EXPLORE

EXPLORE

The 4IR, or the fourth industrial revolution in the last few years, is increasing the use of industrial robots even in small and medium industries worldwide. But as per the Statista report, the industrial robot price has steadily declined in the last decade. From 46,000 dollars in 2010, it was 27,000 dollars in 2017 and is expected to reach 10,856 dollars in 2025. But the use of industrial robots in many sectors, including the plastic industry, is on the rise. Kefan Robot supplies high-speed best industrial robots at competitive costs.

Many students, researchers and customers worldwide ask us for the annual industrial robot price. Though the robot costs are decreasing with increased production using advanced technologies, many factors determine it. Hence, we provide the estimated answers to most questions on robot costs. New industrial robotics complete teach pendants and controllers cost from 40,000 to 80,000 dollars and may cost more depending on the additional application-specific peripherals. Kefan Robot is the leading supplier of industrial robots at competitive costs for many sectors, including the injection moulding processes in the plastic industry.

The reconditioned robots cost less, used robots cost from 20,000 to 40,000 dollars, and application components may cost more. The price of the robots directly relates to the application it performs. And the application determines safety components, peripherals, EOAT and others. Also, the buyers should choose the right robot size considering their workspace requirements, product needs, and reach and payload limits. Kefan Robot offers different industrial robots at competitive costs but with high quality and performance.

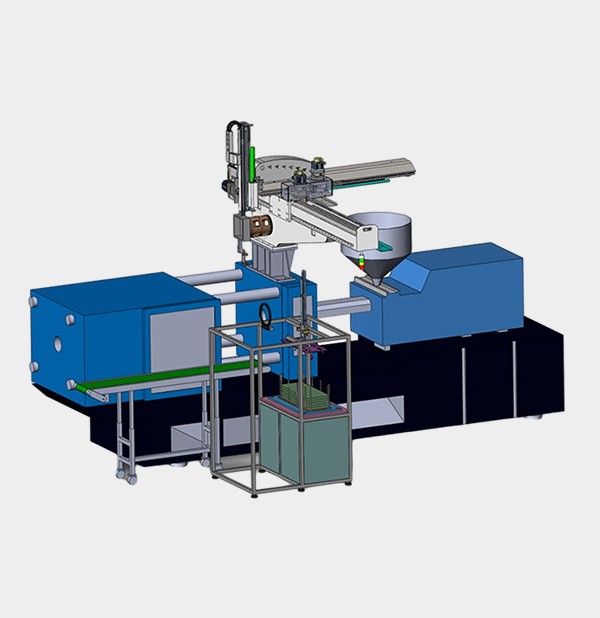

Industrial robots play a pivotal role in the injection moulding process of the plastic manufacturing industry. It helps fast loading injection moulding machines of components to assemble the injection moulded parts. Kefan Robot, for over a decade, has supplied superior quality robots having high precision, speed and stability for the injection moulding process. Also, our best robots help with welding, packaging, and other tasks outside. We supply robots for plastic manufacturers to have a competitive edge over their competitors by increasing their productivity to deliver high-quality plastic products.

Kefan Robot supplies CNC robots to load components into the CNC machines and controls the entire process until unloading the machine. Though the CNC machines are effective and autonomous, they depend on humans to load and unload components into them. And it is only the CNC robotic arm that eliminates human errors and complies with the rules strictly. Hence there is the assurance of product quality apart from the high performance that makes manufacturers use our CNC robots.

In automated welding, the machines do the welding, but it is only the welders controlling and supervising the process. But robotic welding using the welder robots reduces the errors of welders and makes it precise. Quick, safe and with less waste. Kefan Robot, for over a decade, has been the supplier of the best welder robots for use in many welding processes like resistance, arc, spot, laser, plasma MIG and TIG welding. We focus on creating the proper welding jigs and programs into the welding application to make it effective.

Kefan Robot supplies high-quality telescopic robot arms to handle things efficiently. It enables the operator to pick up and manoeuvre big things easily and quickly. Also, it saves time and increases productivity by improving the safety of the employees. Our telescopic robot arm ensures employees do not develop musculoskeletal disorders while lifting heavy loads.

Many industries need ergonomic handling solutions in circular areas where main cranes cannot do it efficiently. Kefan Robot supplies articulated arms used for many applications to provide the best solutions like tool balancing & handling, machine job handling, and specific purpose machines. They have a capacity between 10 to 400 kg to provide quick access and effortless handling of heavy tools. We customize articulated arms with robust and compact designs per our clients' requirements. We aim to provide advanced handling solutions for even heavy things to increase productivity, empower the workplace, enhance workers' efficiency and improvise working conditions and more.

Polishing parts is the final step and essential to ensure their high quality. Manufacturers producing parts in colossal volumes need the best polishing robots to do the repetitive tasks perfectly. It ensures that the parts have consistent shine with a smooth exterior without defects. Kefan Robot offers the best polishing robots at affordable costs to many sectors to produce polished parts to perfection.

Injection moulding robots automate the process by loading the parts into the moulding machine and placing the finished products onto the conveyer belts. Apart from eliminating human errors in repetitive work to cause variations, our injection moulding robots use advanced automated techniques for more precise and flexible production.

For more information on the industrial robot costs and about our many available robots at competitive costs, call us or visit our site Kefan Robotrobot.com.