KAI700D5 -304.76KB

Download BrochureCE Certificate Cartesian Robot

PLC Cartesian Robot

Customized Robot

Pick and Place Robot

Traverse Robot Arm

5-Axis Robot

IML

Technical Details

|

Basic Mechanical Specifications |

|||||||||

|

Model |

Suitable Machine Range |

Axis Strokes ( mm ) |

Driving Method |

C Axis Posture ( 90°) |

Linear Position Repeatability (mm ) |

Net Weight ( kg ) |

|||

|

Traverse |

Crosswise |

Vertical |

Maxi load kg |

C Axis Posture Torque ( Nm) |

|||||

|

KAI700D5 |

60--160T |

1300 |

400 / 400 |

700 |

AC Servo Motor |

5 |

25 |

+- 0.1 |

225 |

|

Minimum Infrastructure Requirements |

|||

|

Working pressure (kgf\cm) |

Consumption (NL\cycle) |

Maximum Power ( Kw ) |

Power ( AC ) Single Phase |

|

5 -- 7 |

1.0 |

1.2 |

220 V, 50/60 HZ |

|

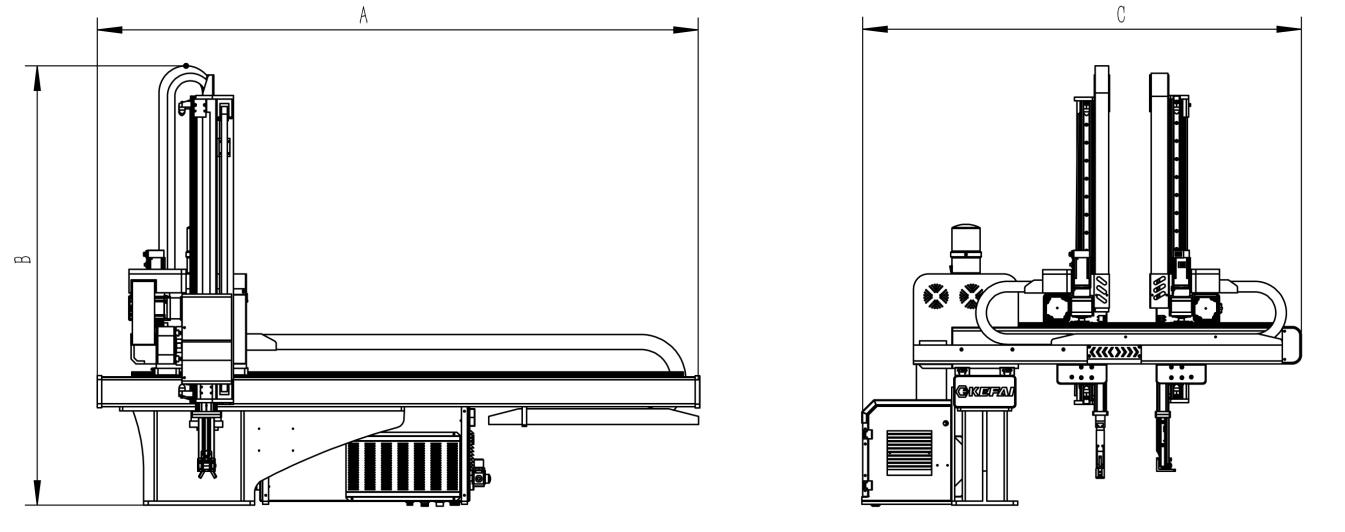

External Size |

|||

|

Model |

A |

B |

C |

|

KAI700D5 |

1850 |

1460 |

1360 |

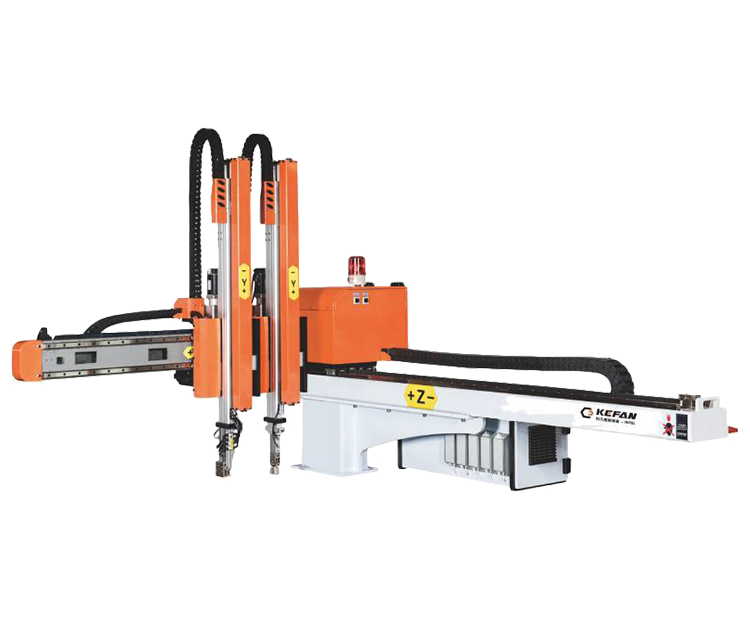

5-Axis Cartesian Pick & Place Robot

Product Name: Cartesian Robot,5Axis, Pick & Place

Application: Take out , Pick and Place

Elevation Speed: 2 m/s

MainComponents: PLC Controller, Bearing, ServoMotor, Pressure vessel,Reducer, linear transducer.

Certification: CE

Ideally designed structure for take-out time reduction (up to 20%)

・Durability has been improved by 60% by analyzing its frame structure and re-evaluating the balance of its center gravity.

・Range of vibration and the convergence time is reduced.

・The balance and driving specification of the arm has been re-evaluated to suppress its twisting and increase moving speed.

・Improved maximum payload performance:

A complex EOAT for insert/multiple placement is adaptable.

The ideally designedKEFAN series contributes to improving productivity in factories, generating faster take-out time and a wider range of the maximum payload.