Basic Mechanical Abilities

|

Basic Mechanical Specifications

|

|

Model

|

Suitable Machine Range

|

Axis Strokes ( mm )

|

Driving Method

|

C Axis Posture ( 90°)

|

Linear Position Repeatability (mm )

|

Net Weight

( kg )

|

|

Traverse

|

Crosswise

|

Vertical

|

Maxi load

kg

|

C Axis Posture Torque ( Nm)

|

|

KOW1200S3

|

350--500T

|

1750

|

860

|

1200

|

AC Servo Motor

|

12

|

35

|

+- 0.1

|

320

|

Minimum Infastructure Requirements

|

Minimum Infrastructure Requirements

|

|

Working pressure (kgf\cm)

|

Consumption (NL\cycle)

|

Maximum Power ( Kw )

|

Power ( AC ) Single Phase

|

|

5 -- 7

|

2.2

|

1.9

|

220 V, 50/60 HZ

|

General Abilities

-

Vacuum line

-

Blow line

-

Sprue Gripper line

-

Telescopic Vertical Axis

-

Eco Model ( Automatic Energy Saving Cycle Feature )

-

Product pickup from fixed and moving platens

-

Conveyor Control

-

Simple Position Teaching

-

Mold Operation Function control

-

Selection of Operator / Non-operator Working Direction

-

Product Sorting and stacking

-

Product sorting in matrix form

-

Soft Sorting / Separation

-

Vacuum level Adjustment on the control Panel

-

Multiple Language support on the control Panel

-

Product Extraction from core in the Mold

-

Sprue Separation

-

Products Separation

-

Crosswise J(Pass) Motion

-

Defective Product Separation

-

Extra Mold Safety Sensor ( Optional )

-

Pause during Operation

-

Stop and start

-

IMM Door Open Permission during Pause

-

C Axis Rotation Control

-

90°Soft Stop

-

Connection Adapter Between Robot and Injection Machine

-

English Software & Multi-language Support

-

Maximum Payload Adjustment

-

Operation Record Feature

-

Alarm Record Feature

-

USB Memory Connection

-

Memory OF up to 99 Molds

-

Ejector Control

-

Euromap 12/67 Robot Interface

-

Overload Protection

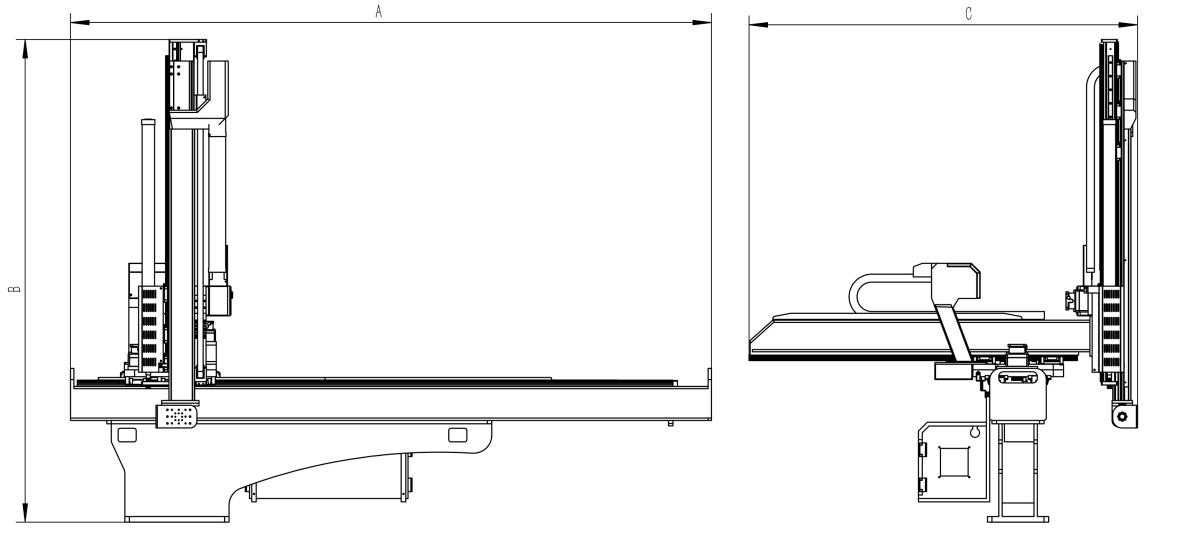

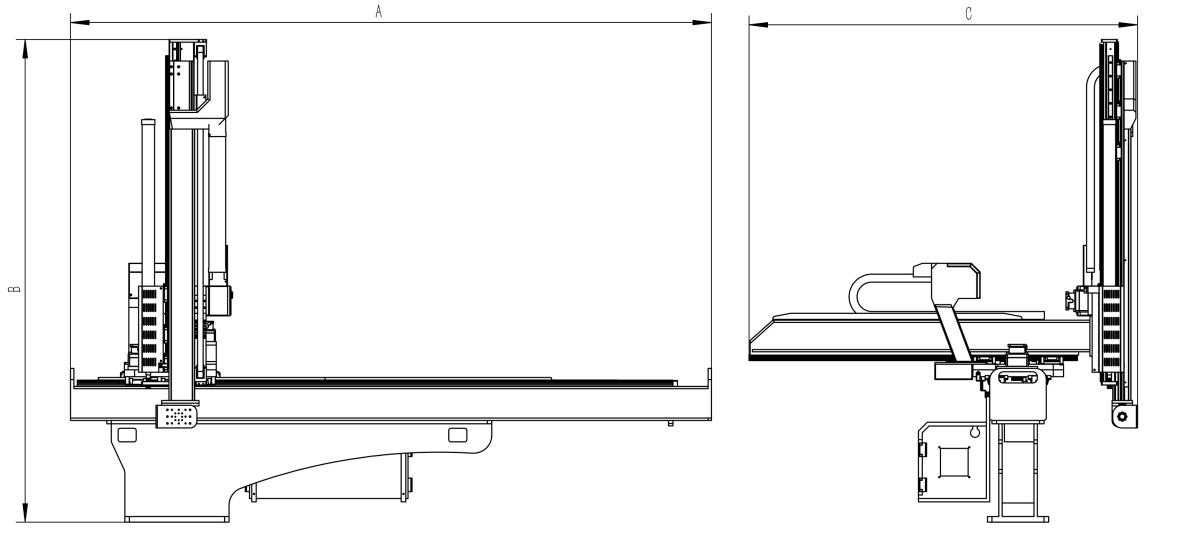

Technical Draw

|

External Size

|

|

Model

|

A

|

B

|

C

|

|

KAW1200S3

|

2310

|

1500

|

1400

|

Key Specifications / Features

Simplify the robot control arm solution

- A 10-30% increase in productivity

- Reduce manual errors

- Improve efficiency and accuracy

- Prevent injuries

- Streamline manual and monotonous process

Ideally designed structure for take-out time reduction (up to 20%)

・Durability has been improved by 60% by analyzing its frame structure and re-evaluating the balance of its center gravity.

・Range of vibration and the convergence time is reduced.

・The balance and driving specification of the arm has been re-evaluated to suppress its twisting and increase moving speed.

・Improved maximum payload performance:

A complex EOAT for insert/multiple placement is adaptable.

The ideally designedKEFAN series contributes to improving productivity in factories, generating faster take-out time and a wider range of the maximum payload.